Packing Jobs: Exploring the World of Packaging and Labeling

Packing jobs are crucial across various industries, ensuring products are safely prepared for transport and sale. From food to pharmaceutical packaging, the process involves precision and compliance with strict regulations. This article explores key aspects of labeling and packaging, the roles in this field, and the importance of meeting industry-specific requirements for safety and quality.

Packaging and labeling represent essential components in the product journey from manufacturer to consumer. These processes ensure products remain safe, identifiable, and marketable across numerous industries. Packaging operations involve various responsibilities including operating machinery, manual packaging, quality control, and compliance with industry regulations. As consumer demands and technology evolve, the packaging sector continues to transform, requiring individuals with varying skill sets and experience levels.

The Importance of Custom Packaging and Labeling

Custom packaging and labeling have evolved beyond mere product containment to become powerful marketing tools. Organizations increasingly recognize that tailored packaging solutions can significantly impact brand recognition and consumer purchasing decisions. Custom packaging allows companies to differentiate their products in competitive marketplaces while communicating brand values through design elements, materials, and presentation.

Beyond marketing benefits, custom packaging solutions address specific product protection requirements. Items with unique shapes, fragility concerns, or special handling needs benefit from packaging designed explicitly for their characteristics. This specialized approach reduces damage during transit and extends product shelf life, ultimately reducing waste and increasing customer satisfaction.

Professionals in packaging operations focused on custom solutions typically engage in collaborating with design teams, understanding material properties, operating specialized equipment, and maintaining quality standards across production runs. These roles often require attention to detail, technical aptitude, and creative problem-solving skills.

Understanding Packaging Labeling in Different Industries

Packaging and labeling requirements vary significantly across industries, each governed by distinct regulations and consumer expectations. In pharmaceuticals, labels must include precise dosage information, ingredient lists, expiration dates, and safety warnings—all subject to strict regulatory oversight. The cosmetics industry emphasizes aesthetic appeal while still providing ingredient transparency and usage instructions.

The electronics sector presents unique challenges, requiring packaging that provides electrostatic discharge protection while clearly communicating technical specifications and safety information. Retail consumer goods often focus on brand storytelling and visual appeal alongside basic product information. Industrial packaging prioritizes durability, clear identification, and handling instructions for workplace safety.

Industry-specific packaging roles typically require specialized knowledge relevant to each sector. This includes understanding material compatibility with products, awareness of regulatory requirements, and familiarity with industry-standard labeling practices. Many positions in the field involve certifications or specialized training particular to industry packaging standards.

The Role of the Packaging Labeling Machine

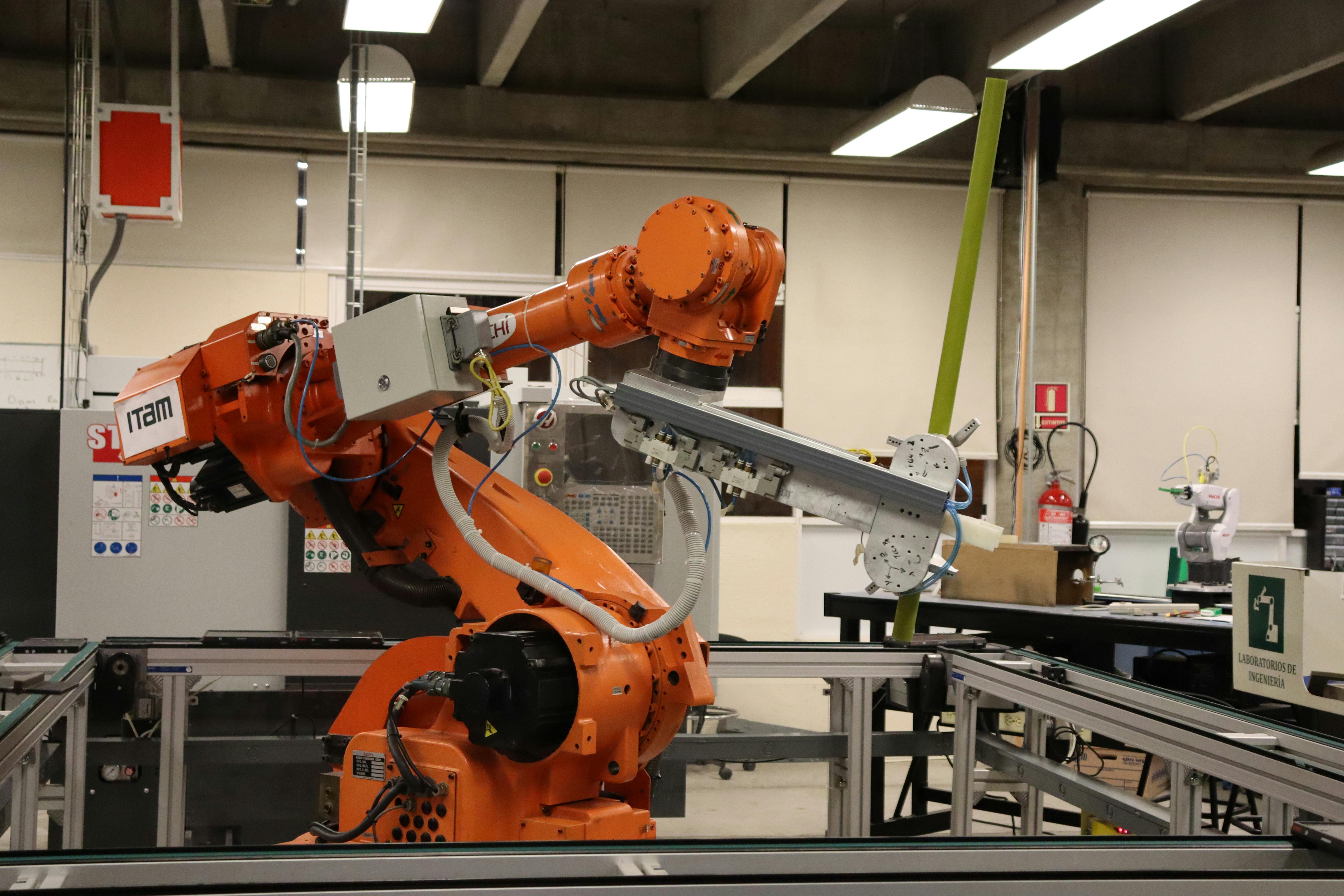

Automation has revolutionized the packaging industry, with packaging labeling machines standing at the forefront of this technological advancement. These sophisticated systems apply labels with precision and consistency that manual application cannot match, significantly increasing production speeds while reducing labor costs. Modern machines can apply various label types—including pressure-sensitive, shrink sleeve, and in-mold labels—to containers of different shapes and sizes.

Working with packaging labeling machines requires technical skills to program parameters, monitor operations, troubleshoot issues, and perform routine maintenance. This work combines mechanical aptitude with attention to detail, as even minor misalignments can result in costly production errors. As technology advances, these positions increasingly involve familiarity with computerized control systems and digital interfaces.

The field of packaging machinery includes various roles such as maintenance technicians, equipment specialists, and automation engineers. These positions typically involve technical expertise, with potential pathways into production management or specialized consulting work.

Regulatory Compliance in Packaging and Labeling

Regulatory compliance represents one of the most critical aspects of packaging and labeling operations. Government agencies worldwide establish and enforce regulations governing product packaging to ensure consumer safety, accurate information, and environmental protection. These regulations may specify required information, minimum text sizes, warning symbols, and even packaging materials permitted for specific product categories.

Compliance professionals in packaging environments must stay current with evolving regulations across different markets. This includes understanding country-specific requirements for exported products, which may differ significantly from domestic standards. The consequences of non-compliance can be severe, ranging from product recalls and fines to legal liability and reputational damage.

Regulatory compliance work in packaging typically involves document management, quality assurance testing, label verification, and coordination with legal departments. These responsibilities require meticulous attention to detail, strong analytical skills, and the ability to interpret complex regulatory language. As international trade expands, knowledge of global packaging regulations becomes increasingly relevant to organizations with multinational distribution.

Packaging Labeling in Food Processing

Food processing presents particularly stringent packaging and labeling requirements due to safety concerns and consumer information needs. Labels must accurately display nutritional information, ingredient lists, allergen warnings, and preparation instructions—all while meeting regulatory standards for food contact materials. The packaging itself must protect contents from contamination while maintaining freshness throughout the distribution chain.

Professionals in food packaging environments operate under strict hygiene protocols and quality control procedures. They must understand food safety principles, allergen management, and proper handling techniques for different food categories. Specialized knowledge of packaging materials safe for food contact is essential, as certain substances can migrate from packaging into food products.

The food packaging field encompasses various roles including quality assurance specialists, packaging technologists, food safety coordinators, and production supervisors. These positions typically involve food safety certifications alongside packaging expertise. As consumer demand for transparency increases, clear nutritional labeling and sustainable packaging solutions continue to be important aspects of the food processing sector.

Understanding the Packaging Industry Structure

The packaging industry is structured across multiple segments, each with distinct functions and expertise requirements. Primary packaging directly contacts the product, secondary packaging groups primary packages together, and tertiary packaging facilitates bulk transportation. This layered approach ensures products move efficiently through supply chains while maintaining integrity and visibility.

Packaging operations typically include design, production, quality control, and distribution phases. The design phase involves material selection, structural engineering, and graphic elements that balance protection, marketability, and cost-effectiveness. Production encompasses material preparation, forming, filling, sealing, and labeling—often using specialized equipment for each process.

Quality control systems monitor consistency, safety, and compliance throughout the packaging process. This includes visual inspections, automated scanning systems, and regular testing against established standards. Distribution considerations include stackability, space utilization, and protection during transit, with packaging engineers often designing solutions specific to particular logistics challenges.

Sustainability has become increasingly central to packaging operations, with organizations exploring recyclable materials, biodegradable alternatives, and designs that minimize material usage. This environmental focus represents a significant shift in industry priorities, driving innovation in both materials science and structural design approaches.

The packaging and labeling sector continues to evolve with technological advancements and changing consumer expectations. The industry encompasses numerous specialized areas across various sectors of the economy, combining technical expertise with practical production knowledge to deliver solutions that protect products while informing consumers.